Proven solutions for indoor air quality

About Airocide Purification Technology

Allow us to introduce you to Airocide, a non-chemical (no ozone), commercial air purification technology. Our commercial air sanitation solution was developed from NASA technology and offers the latest innovation in airborne cross-contamination protection for your company, your valuable brands, and your products. The applications are almost infinite when it comes to improving and protecting commercial indoor air quality (IAQ), both effectively and cost efficiently. Airocide works for NASA, Airocide will work for you.

The Airocide story begins in space with NASA. They had a problem with ethylene gas (C2H4)! NASA pioneering space travelers needed to grow and manage their own crops. This required the development of space-age greenhouses where astronaut farmers could experiment with harvesting large-scale food crops. Ethylene is a naturally occurring, odorless, colorless gas given off by plants that speeds up the ripening of fruits, vegetables and the aging of flowers, encouraging decay. Comprised of carbon and hydrogen, in closed growing environments, like on a spacecraft or in a terrestrial greenhouse, ethylene builds up quickly and plants mature too fast. Therefore, ethylene gas removal is important to preserving crops not just in space, but also on Earth. Because commercial grocers, cold storage warehouses and florists also have an equally specific interest in removing the ethylene gas. If they don’t it ultimately shortens the shelf life, storage life and home life of their products.

Airocide completely mineralizes (turns organics into carbon dioxide and water vapor) airborne bacteria, mold, fungi, mycotoxins, viruses, allergens, Volatile Organic Compounds (VOC’s like ethylene), and odors. What’s more, the commercial device does not use nor produce ozone or any other harmful byproducts. This Airocide technology was first launched aboard Space Shuttle Columbia mission STS-73, where onboard the spacecraft the device was used successfully to preserve crop growth by removing ethylene gas and other airborne contaminants.

HOW AIROCIDE WORKS

The technology is based on revolutionary research from NASA, University of Wisconsin (UW), and Wisconsin Center for Space Automation and Robotics (WCSAR), developed originally for the NASA space program. The Airocide commercial air purification systems use a patented technology to kill more than 99.99% of the airborne pathogens that pass through its processor. Airocide completely mineralizes (destroys) them, converting them to carbon dioxide and water vapor.

The air purifying technology in Airocide was proven to kill 99.999987% of Bacillus thuringiensis, a close cousin to the anthrax bacteria, in a single pass through its reactor.

The air purifying technology in Airocide was proven to kill 99.999987% of Bacillus thuringiensis, a close cousin to the anthrax bacteria, in a single pass through its reactor.

Among other bacteria, fungi and viruses, photocatalytic oxidation technology kills airborne Lactobacillus, which can be a problem in wine, beer and other beverage and food processing facilities.

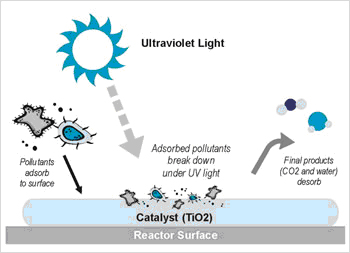

Photocatalytic Oxidation (PCO)

The technology used in Airocide’s commercial air purification solution combines two known pathogen-killing techniques, Photacatalytic oxidation (PCO) and ultraviolet light to destroy harmful airborne microbes. The oxidant used in PCO is the oxygen that makes up 20% of our air. Because the concentration of oxygen in air is so much larger than the (total) concentration of gaseous indoor air pollutants, it is not necessary to employ additional oxidants such as ozone (O3) or hydrogen peroxide (H202). The system produce no ozone.

Titanium dioxide (TiO2) is the photocatalyst used. A unique process is used to create the patented TiO2 formula that coats the catalyst material. When this material is irradiated with the ultraviolet photons from the lamps inside, hydroxyl radicals and super-oxide ions are formed. These elements will oxidize (reduce to trace elements of carbon dioxide and water) volatile organic compounds (VOC’s) absorbed on the catalyst surface. They will also kill and decompose airborne pathogens. Because the organic material is completely oxidized by this process, the photocatalytic reactor is self-cleaning relative to organic material on the catalyst surface.

The History of PCO

PCO has gained attention in recent years as an approach to treat gaseous pollutants and microbes. Over the past quarter century, construction practices have favored the design of tight buildings to reduce energy costs of conditioning the indoor air. However, without sufficient ventilation, the concentration of volatile organic compounds (VOCs) can be increased. Indoor air contamination by undesired VOCs is a possible causative agent of the sick building syndrome.

PCO has gained attention in recent years as an approach to treat gaseous pollutants and microbes. Over the past quarter century, construction practices have favored the design of tight buildings to reduce energy costs of conditioning the indoor air. However, without sufficient ventilation, the concentration of volatile organic compounds (VOCs) can be increased. Indoor air contamination by undesired VOCs is a possible causative agent of the sick building syndrome.

The first published report of photoreactivity (the precursor to PCO) was made numerous potential applications of PCO. Studies involving gas phase PCO are relatively few in number compared with the published studies of the photocatalytic treatment of compounds in aqueous media. However, there is increasing interest in gas-solid PCO because of the potential application to contaminant control in indoor environments including residences, office building, factories, aircraft, and spacecraft in 1921. However, photocatalysis studies only began in 1971.

Airflow Explanation

While Airocide Photocatalytic Air Purifying Systems are not integrated or built into the central heating, ventilation and cooling (HVAC) systems of a building, its room-to-room performance is enhanced by super pure air mixing and traveling around the space via the room’s natural and forced air movement. In essence, the Airocide system’s effectiveness in a given coverage area is enhanced by the HVAC system’s interconnected ductwork. Airocide air purifiers can be installed attached to walls or ceiling in any room of a building and its benefit can be seen in other rooms as long as that room location has an air conditioning/heating inlet and air return. In this way air ‘communicates’ throughout the interconnected and adjacent rooms.

Air purification and removal of air contamination occurs by multiple air passages through the Airocide system’s photocatalytic chamber where a chemical reaction takes place yielding more than 99.99% pure air that then mixes with remaining contaminated air. A pure – to – contaminated mixing then occurs multiple times over several hours resulting in the lowering of both solid particles and gaseous contamination in the total space.

As new contaminants are introduced by opening doors to the outside or internally generated gaseous chemicals or human carriers of new organic matter the air purifying system continues 24/7 processing the air. The key to maximizing its effectiveness is the continuous operation and exceptionally high single pass removal capacity. Only super pure air and trace amounts of water vapor and carbon dioxide pass out of the system.

As new contaminants are introduced by opening doors to the outside or internally generated gaseous chemicals or human carriers of new organic matter the air purifying system continues 24/7 processing the air. The key to maximizing its effectiveness is the continuous operation and exceptionally high single pass removal capacity. Only super pure air and trace amounts of water vapor and carbon dioxide pass out of the system.

Just as the colored dye in this glass of water will eventually diffuse into the entire glass, an Airocide unit mixes with a room or building air to process out contaminants.

The most functional

The most innovative

The most trusted

Even the big guys use us